FEATURED

PRODUCT

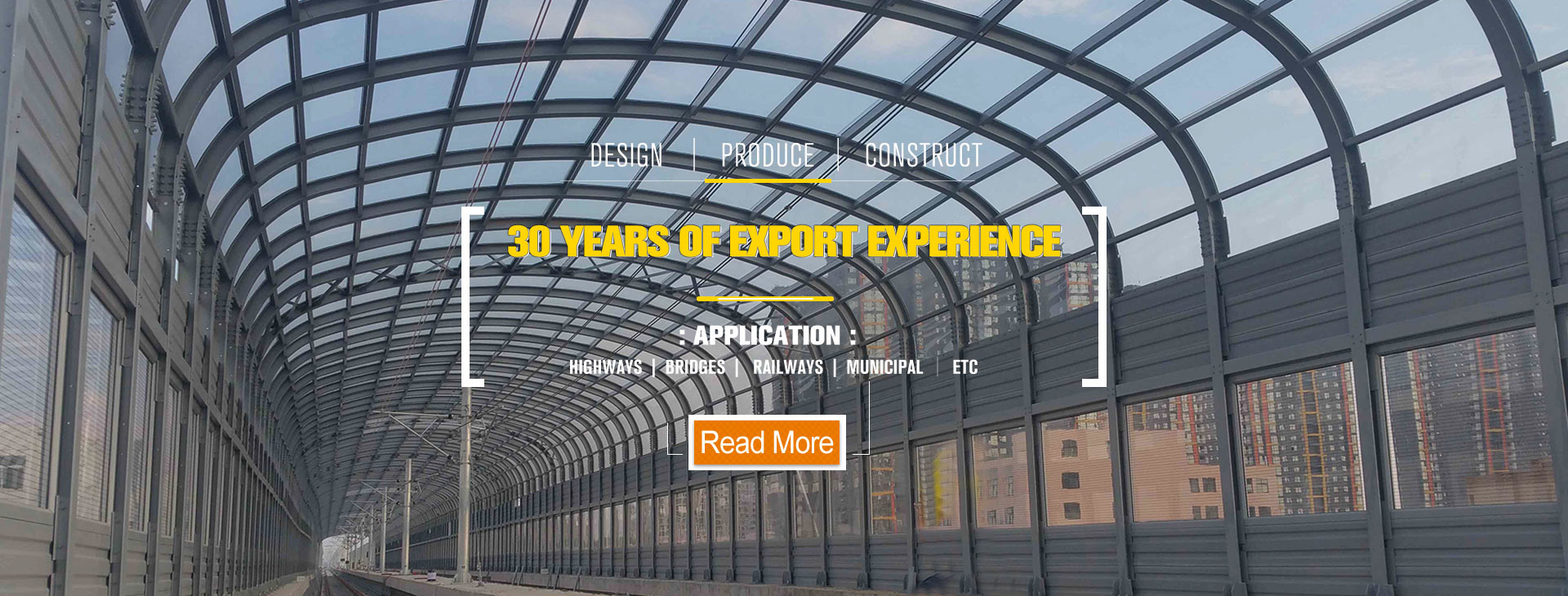

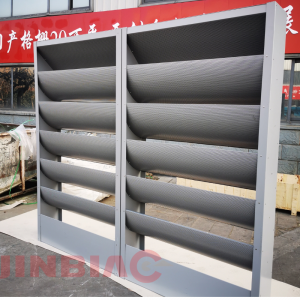

NOISE BARRIER

Hebei Jinbiao Construction Materials is founded in 1990 specializing in the production of construction material. Our factory occupies more than 200,000m2 area, with more than 620 employees, 60 specialists, registered capital of RMB 60.4 million, reaching 500 million yuan of liquidity.In Shijiazhuang, 26 December 2014, the company was listed on the stock exchange, becoming the first locally listed company in the area.

YOUR SPACE MADE QUIET

HAS BEEN DELIVERING THE HIGHEST QUALITY GOODS IN BOTH SOUND ABSORPTION &BARRIER SERVICES.

Superior systems expertly designed for safety, noise reduction, and wind control on highways, bridges, buildings, and beyond.

FENCE

NEW PRODUCT

MISSION

STATEMENT

Hebei Jinbiao Construction Materials is founded in 1990 specializing in the production of construction material. Our factory occupies more than 200,000m2 area, with more than 620 employees, 60 specialists, registered capital of RMB 60.4 million, reaching 500 million yuan of liquidity.In Shijiazhuang, 26 December 2014, the company was listed on the stock exchange, becoming the first locally listed company in the area, the products are also registered gold standard mesh, noise barrier and aluminium formwork brand.